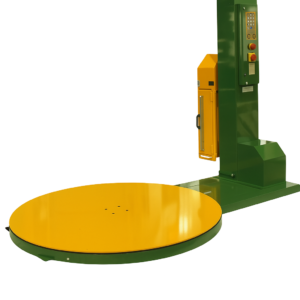

Horizontal Stretch Wrapping Machine

Efficiently wrap long and irregularly shaped loads like pipes and timber with our Horizontal Stretch Wrap Machine—designed for strength, stability, and seamless automation.

- Description

- Additional information

- Features

- Benefits

Description

A Horizontal Stretch Wrap Machine, also known as an Orbital Wrapping Machine, is specifically designed for wrapping elongated loads such as timber, aluminum bundles, plastic pipes, and similar materials. The orbital structure allows the load to pass through a horizontal wrapping ring, where it is stabilized using stretch film and supported by conveyor transmission.

This intelligent system offers consistent wrapping with the option for customized wrapping positions. Built with a heavy-duty forged steel frame, the machine ensures strength, durability, and reliable performance. Optional infeed and outfeed conveyors can be added as per operational requirements.

Additional information

| Disk Diameter | 500 Mm. (As Per Our Design) |

|---|---|

| Minimum Load Dimensions | 100 X 100 X 200 |

| Maximum Load Dimensions | 300 X300mm (Length Any) |

| Maximum Load Weight | 2500 Kgs. |

| Spool Carriage | Motorized Power Pre-Stretch Carriage with Pre-Stretch Ratio Adjustable Up to 100 % |

| Turntable Speed | 0-12 R.P.M. |

| Electrical Drives | Disk 1 Hp Motor / Pre-Stretch & Film Elevator 0.5hp |

| Film Width | 150-200mm (Max.) |

| Film Roll Id | 76 Mm |

| Film Diameter | 200mm (Max.) |

- Handy Start Stop Flexible Hanging Switch Panel

- Soft Start / Stop Through Ac Invertor

- Plc Controller

- Safety Device by Micro switch

- Tension to Load Adjustable

- Disk Speed Adjustable

- Film Carriage Speed Adjustable

- Fixed Upward Downward Spool Carriage Speed with 20 % Overlap.

- Automatic Load Height Sensing by Photocell.

- Turntable Rests in Home Position.

- Huge cost saving than foam protective or any other protective packing

- Very fast packing systems vs Manual packing

- Less operator required

- Best protection than other protective packing with elegance

- Can use for wide range of products.