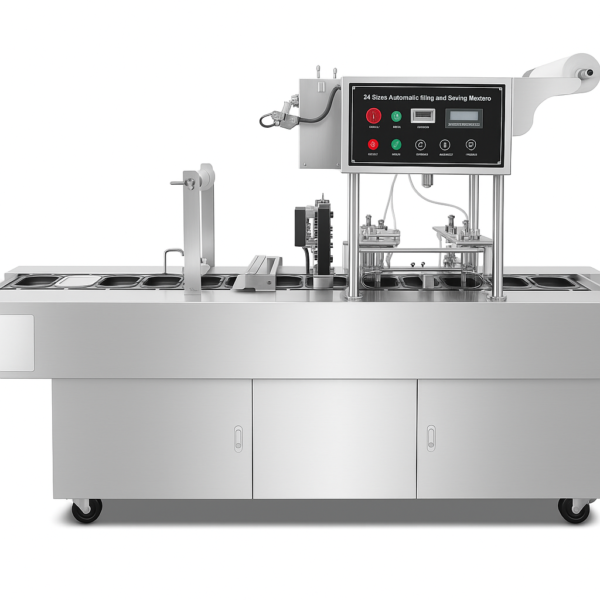

Automatic Tray Sealer Machine

The Automatic Tray Sealer Machine is a high-efficiency packaging system that seals trays with airtight precision, ensuring freshness and protection. Widely used in food, pharmaceutical, and industrial applications, it offers automatic feeding, filling, and sealing with user-friendly controls and fast changeovers—perfect for high-volume operations.

- Description

- Additional information

- Features

Description

An Automatic Tray Sealer Machine is a high-performance packaging solution designed to seal trays efficiently and securely. It is commonly used in the food, pharmaceutical, and industrial sectors to preserve product freshness, protect against contamination, and extend shelf life. The machine automatically feeds, fills, and seals trays with a secure, airtight seal, enhancing productivity and consistency.

Its advanced technology allows for quick changeovers, user-friendly operation, and minimal downtime, making it ideal for high-volume packaging needs.

Additional information

| MOC | SS |

|---|---|

| Voltage | 220/50,110/60 |

| Motor Power | 500 W |

| Speed | 800 Tray/ Hr. |

| Distance between two trays | 15mm |

| Temperature Range | 0-400 mm |

| Tray Size | 140x190mm (Height Max 125 mm) |

| Panel Branded | Brought Out Items with Micro Control Base Systems |

| Working Period | 24 x 7 |

- Easy to operate -minimal operator training

- Fast warm up time

- Seals any thermoplastic material including PE, PP, and laminates trays

- Symmetrical pneumatic pressure gives excellent sealing to the product.

- Sealing method – Casting dia with inbuilt heater

- Two Dia press cut gives faster production.

- Unit feeds Left to Right

- Equipped with an emergency stop button

- Can easily be converted to a vertical configuration with an optional converting kit.